Transmission Components

Blue Ridge Pressure Castings specializes in die casting many important transmission components for the automotive and heavy truck industries.

An automatic transmission is an extremely complex combination of mechanical, electrical and hydraulic components working together. Particularly in the heavy truck market, Blue Ridge aluminum die castings are put to extreme conditions and environments. The fact they are so reliable and quality certified has led to Blue Ridge gaining a very good reputation within the industry.

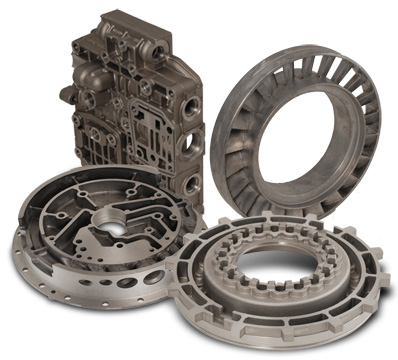

The most common transmission components Blue Ridge supplies are valve bodies, stators and clutch pistons. Each play critical roles within a transmission and demand for superior quality and reliable parts is high. Clutch pistons are part of the automotive gear system, valve bodies work within the hydraulic system and stators are components of the torque converter.

Valve Bodies:

Diecast valve bodies for automatic transmissions have long been considered one of the most difficult aluminum die castings to produce. The complex shape of the aluminum valve body results in a casting die that is very complicated to build with fragile interlocking die components. Only the most disciplined of shops are capable of operating and maintaining these dies.

Quality demands for the production of valve bodies challenge the capabilities of the die cast process. Porosity characteristics and permissible limits are tightly specified for sealing surfaces, channel areas, SAE connections and control valve bores. The highly interrupted metal flow impedes all attempts at a directional flow path. Hence it becomes imperative to utilize both experience and the best simulation techniques to optimize cavity fill conditions. To minimize porosity many techniques including vacuum are utilized to produce high integrity castings

Blue Ridge has established itself as a niche supplier of transmission valve bodies and channel plates for a large range of non-mainstream vehicle applications. Quantities range from a few pieces to 100,000 units. Valve bodies ranging in size from three tenths of a pound to 13 pounds are diecast. Parts can be supplied either cast and trim or fully machined.

Stators:

Most automotive applications produce the impeller, turbine and stator as a complex assembly of stamped steel parts due to the very complex die configuration required. In the attached picture a complex turbine produced by Blue Ridge as an aluminum die casting can be seen. The vanes are highly optimized for efficient fluid flow, however the design requires a very complicated die construction where the diecast part is ejected via a helical mechanism in the die. While these techniques are utilized in plastic injection molding, the high pressures and temperatures of the diecast process make this most difficult to achieve in aluminum die casting.

Blue Ridge has a proprietary die construction technique providing a seal capable of tolerating both the die expansion and the pressure of the molten metal between the moving members of the die. It is this proprietary design that allows the helical ejection mechanism to work satisfactorily.

Many of the unique features used to produce the parts seen in these pictures can be applied to similar aluminum diecast products:

- Thin radial fin designs

- Helical draw to remove undercut sections from the die

- Complex configurations

- Elimination of fabrications

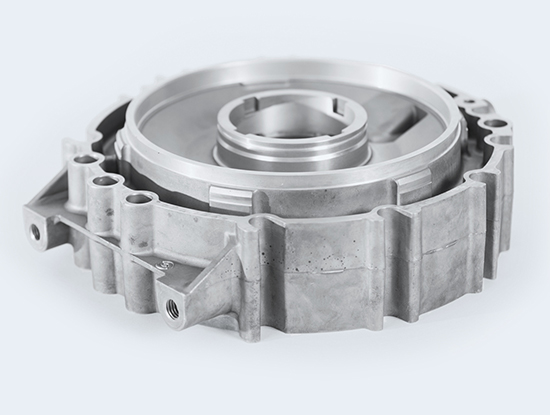

Clutch Pistons:

Over 100 different transmission clutch piston designs have been die cast at Blue Ridge, and extensive knowledge has been acquired in both design and production of these pistons.

Piston size has ranged from two tenths of a pound to over 12 pounds with both simple and complex shapes being cast. Quantities for specific designs have ranged from a few pieces to several hundred thousand pieces annually.

The manufacturing process developed at Blue Ridge to produce clutch pistons has been tailored to address the specific concerns of piston use and assembly. This process includes both casting and machining. Some of the techniques utilized are:

- Advanced die design utilizing simulation techniques.

- Utilization of power venting or vacuum systems

- Thermal analysis of the die-casting die.

- Automated cast/trim cells.

The machining operations range from automated machining cells with multiple operations to simple CNC turning cells. Tooling is custom designed to meet demanding diameter, roundness and concentricity specifications. Pressure tightness and cleanliness are addressed through custom designed equipment specific to the manufacture of transmission components:

- Collet chucks

- Vision systems

- Hole drilling and verification

- Robotic handling

- Traceability

- Porosity verification