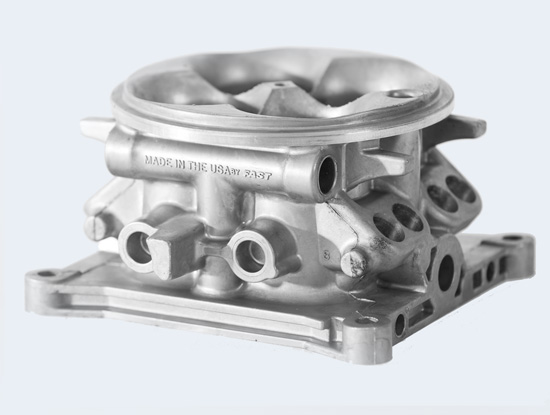

Quality Program and Certifications

Quality Lab

The Quality Lab at Blue Ridge supports both the casting and machining operations. Our highly trained staff uses the latest equipment to ensure compliance with the industry’s most demanding specifications.

Equipment:

-

- 3-Coordinate Measuring Machines with full surface profiling capability

- Romer Laser Digital Surface Scanner

- Optical Comparator

- Mahr Surf Digital profile generator

- X-Ray Machine

- Lab Quality Spectrograph

Certifications:

- IATF 16949

- ISO 14001