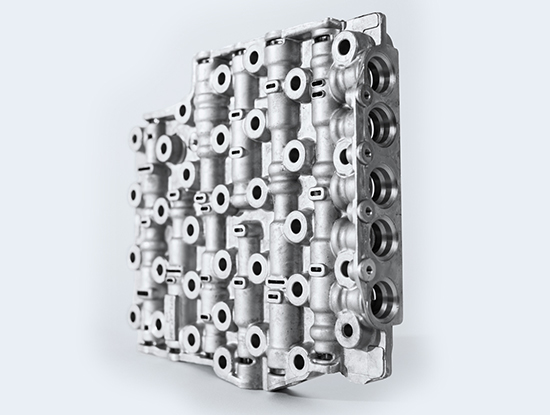

Tool Design

We use sophisticated tool design to maximize the cost efficiencies and quality possible through high pressure aluminum die casting. Blue Ridge has led tool design for some of the most complex and demanding parts in the industry. World class tool design requires that we take into account factors such as:

- Mold Flow

- Back Pressure and/or Vacuum

- Mold Release

- Injection Ports

- Flow Rates

- Solidification Characteristics

- Parting Lines

- Tool Maintenance

- Heating and Cooling Requirements

- Thermal Shock Factors

- Deformation due to Pressure and Temperature Variations

- Core Designs

Many of our customers have found that no other die caster can deliver the right tools for complex parts as effectively as Blue Ridge. Our team prides itself in developing cost effective solutions to meet difficult customer requirements.